How Leather is Made?

How Leather is Made? | Leather Production Process

The way leather is made has not changed much in thousands of years.That said, getting leather ready for making products is not an easy process. It usually takes about 10 workdays to change animal skins into leather. Skilled workers called tanners know a lot about their craft, and they do their jobs very carefully. Making leather takes a lot of time and involves many steps, which is why leather products can be expensive.

Hides are animal skins used to make leather, and they need to be kept properly to stop them from going bad. These ways to preserve food usually include adding salt, freezing, cooling, or using chemicals.

Soaking means putting something in water for a while so it gets wet or soft. After the skin has been treated, it is soaked in water for many hours or even days. In this step, the goal is to moisten the hide again and get rid of any extra salt or dirt. For example, dirt might have gotten stuck during shipping.

Painting, don't let the word confuse you. When talking about how leather is made, painting means taking off the wool from sheepskin with chemicals called sulphides.

Liming means adding lime to soil to make it better for growing plants. Lime helps to balance the soil's acidity and can improve its quality. Liming has several uses, but its main purpose is to get rid of unwanted hair from the animal skin by using an alkaline substance. After the hair is taken off, we have the animal's skin. This is usually called a pelt.

Fleshing means adding detail or depth to something, making it more complete or full. Fleshing is when a pelt is put through a machine that takes off any leftover meat from the inside. Sometimes, a fur skin is cut into layers at this point.

De-liming means removing lime, which is a mineral that can build up over time. This process helps keep things clean and working properly, especially in appliances like kettles or dishwashers. This step includes the careful removal of the alkali from the hide. It's important to make this change slowly because a quick shift in acidity could damage the tissues.

Bating, enzymes are used on the skin to make it flat and soft.

Pickling is a way to preserve food by soaking it in a salty or acidic solution. To tan hides, they need to be a little sour. So, pickling means using weak acids or salt water. If a pelt won't be tanned for a few months, a strong mixture can be used to keep it from spoiling.

De-Greasing, before tanning, a hide needs to have any extra grease taken off using water or a gentle cleaner.

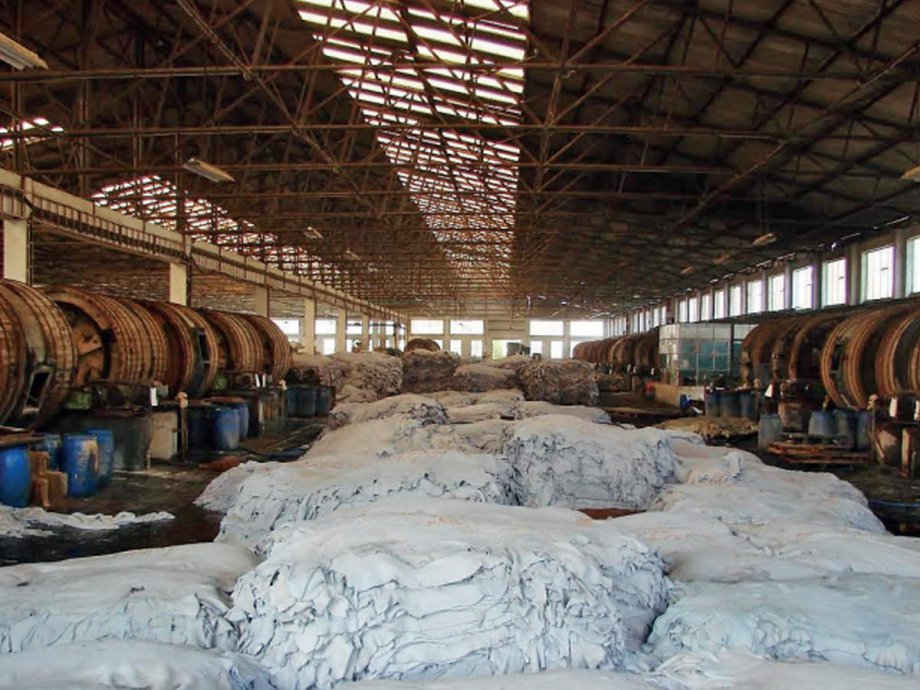

Tanning means getting a darker skin color from being in the sun or using a tanning bed. Tanning changes the structure of animal skin so that it can resist chemicals, water, and germs. In this step, the proteins in the animal skin turn into a strong material. It is usually done by using:

Minerals: A mineral, like chromium salts, is the most common material used for tanning leather.

Oils: When animal skin is treated with oil, it becomes softer and is better for making stylish items.

Vegetables: Plant materials can make strong, thick, and brown leather, which is great for belts, shoes, bags, and cases.

After a skin is treated to become leather, there are still a few more steps to complete before it can be sold to a manufacturer.

Splitting, in this step, a machine cuts the leather into two pieces. One of the layers will be smooth and not grainy. This material can be made into suede or have a fake grain finish added to it.

Shaving, A different machine is used to smooth the side of the piece that does not have a grain texture. This is how leather is made to be the right thickness.

Neutralization means making something that is not neutral, like an acid or a base, balanced or neutral by mixing it with something that has the opposite effect.

This step in making leather is done to get rid of any leftover chemicals from earlier processes. Extra tanning materials can be used to give a specific look or feel to the final product.

Dyeing, depending on what the finished leather will be used for, different colors can be added at this point. This is how leather is made in different colors like black, red, brown, and white.

Fatliquoring is the process of adding fats or oils to leather to make it soft and flexible. This process means putting oil on the leather to make it soft and bendy. This is very important when making leather for fashion because if there's no oil, the leather will dry out and become hard.

Samming, the leather needs to have the water removed from it before it can be used for making products. About half of the water is taken out using several different machines. The leather is now pulled tight, and its surface is made smooth. This also dries out the moisture left in the leather even more.

Final Drying, Leather is usually dried until it contains less than 20% water.

Staking & Dry Drumming, to make the leather soft and easy to bend, it is massaged more in a special machine. This process pulls the fibers apart. After it's finished, the leather goes into a spinning drum for thorough shaking.

Buffing and Brushing, the top layer of the leather has been completely taken off by rubbing it down to make it feel softer or to make it thinner. After buffing, a detailed brushing is done to get rid of any dust that has collected.

Finishing is done in leather making to make the color even, fix any flaws on the surface, adjust the shine, and add a layer that protects against water.

Final Selection, before selling the leather to a manufacturer, the tanner needs to check the color brightness and evenness, as well as how it feels, its softness, thickness, and surface quality. Any natural flaws, like scratches, should be recorded during the final inspection.

Measurement, the final product is ready. This is how leather is made from beginning to end. The last thing to do in this step is to measure the size of each piece, since leather is sold by measurement. To make sure everything is accurate, machines take the measurements.

FAQ

How Long Does It Take to Make Leather?

The process of making leather from animal hides can take a few weeks to several months, depending on how the leather is tanned. The process of making leather starts with getting the raw materials ready. Chrome tanning is a process that takes about 24 hours. In contrast, vegetable tanning, which uses tree bark and plant materials, can take a month or longer. Extra steps like dyeing the leather (which takes 8 hours) and the finishing stage can add a few more days to the schedule. The drying process and vacuum drying are important steps in making good leather.

Is Leather Production Environmentally Sustainable?

Making leather uses animal products and leftovers from the meat and dairy industries that would otherwise be thrown away. The tanning process uses a lot of chemicals, including chromium, and needs a lot of water, which must be managed carefully to follow environmental rules. Today, leather makers use recycling methods to reduce their impact on the environment. The leather industry has problems with chromium waste and how to get rid of it. However, new technology has helped lower pollution by managing waste properly.

What is the difference between real leather and faux leather?

Natural leather comes from animal hides, like cow skin. It goes through a detailed process called tanning that changes its protein and fiber structure. This flexible material can be made into different kinds of leather, such as full-grain leather, top-grain leather, and split leather. The natural pattern in the material makes it strong and allows air to flow through it. Over time, it gains a shiny finish that is typical of leather. Faux leathers and synthetic materials, like vegan leather and mushroom leather, are usually cheaper and easier to make. However, they might not be as strong or durable as real leather.

How can I tell if my leather is made with chrome or vegetable tanning?

Chrome-tanned leather, often used in leather jackets and car interiors, is usually softer and more water-resistant. Vegetable-tanned leather is thicker and stiffer, which is why it's often used for making high-quality items like the covers for Japanese swords. The top layer of chrome-tanned leather usually has a little blue color before it gets dyed. Different ways of making leather lead to different qualities. Some leathers are special and rare, while others are more common. Each type is good for different uses.

How should you properly care for leather products?

To take care of good leather, use a damp cloth (not soaked) to clean it, because too much water can harm the leather. Using products like neatsfoot oil or mink oil regularly is very important. The finishing process might need regular oiling and some special items for cleaning and taking care of it. To keep leather items in good shape for a long time, keep them away from extreme heat, cold, and moisture. This beginner's guide helps you take care of leather items, from old times to today.

Summary

Making leather is a complex process that requires basic materials, water, and chemicals. Just like with bags, look for leather items that are durable and stylish. That's probably another reason why Steel Horse Leather is now a popular name for high-quality leather.