Types Of Leather

Types Of Leather

Categorisation of typologies

It is important to understand that when discussing about the different types of leather, the issue can be discussed on many levels, in reality the various kinds of leather currently on the market can be categorized according to various parameters:

- The tanning form

- "The epidermis layer that is used" (Split "or" Top-Grain)

- The animal which was used

- The finishing form of the surface

- The cut and the form

- Usage

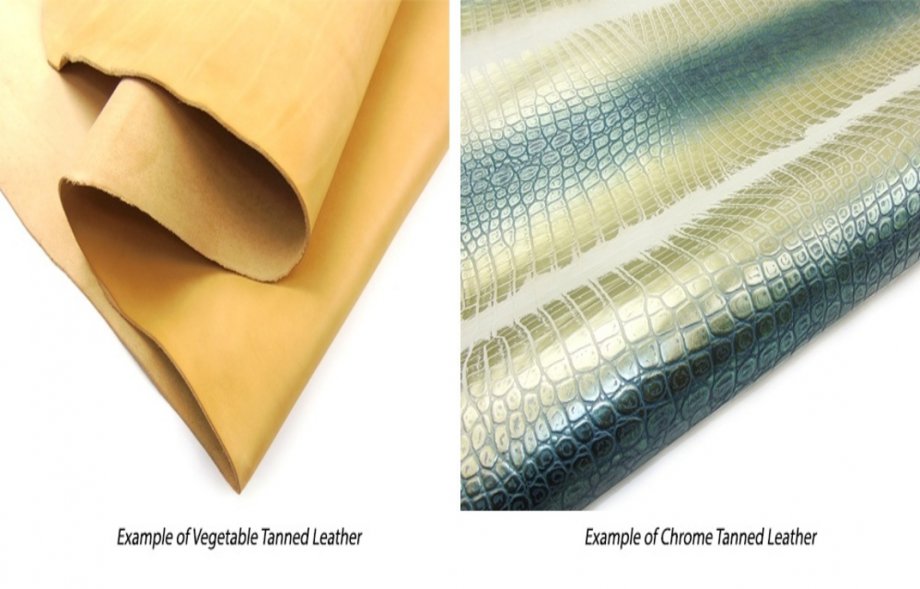

First, the determination of the type of care and tanning to which they are exposed in order to maintain and process them is the first step in determining the key characteristics and variations between the skins. This is because the choice of the tanning form affects the finishing and cutting of the different pieces, which in turn affects the material's future uses. For instance, if a bull hide is left intact, it will undoubtedly be chrome tanned and used for furniture, whilst it will be broken into separate sections in the case that this can be vegetable tanned, and the primary use will be that of belts and saddlery.

According to the process of tanning

The "tanning industry" is widely described as the collection of all the processes leading to the production of leather, such as the industrial sector manufacturing leather, recovering and improving a food industry by-product: raw animal skin from slaughterhouses.

Tanning is the first step. Tanning is the chemical method that turns rot-proof skin into a rot-proof cloth, i.e. leather. Chromium tanning and vegetable tanning are the most similar types of tanning: the key distinction between the two is the use of various tanning chemicals, in the case of chromium tanning, of chemical origin, and in the case of vegetable tanning, of organic sources. Thus, we can infer that we can classify two major types of leather based on the tanning process used:

According to the layer of skin (Split vs Grain)

In certain situations, there is a method called "splitting" of the skin prior to tanning. Originally too heavy for use in any form of manufacturing, leather coats must be broken both for process purposes and for production and economic reasons. The full-thickness skin is divided horizontally by a moving blade and separated into two parts: "Cut," the layer obtained from the side of the beef, and "Grain," the one obtained from the portion of the fur of the animal. Thanks to this approach , two items with very distinct features and intended uses are obtained that differ according to the corresponding processing steps. The bovine break, for example, afterwards tanned with chrome, would be a fine commodity for making shoes.

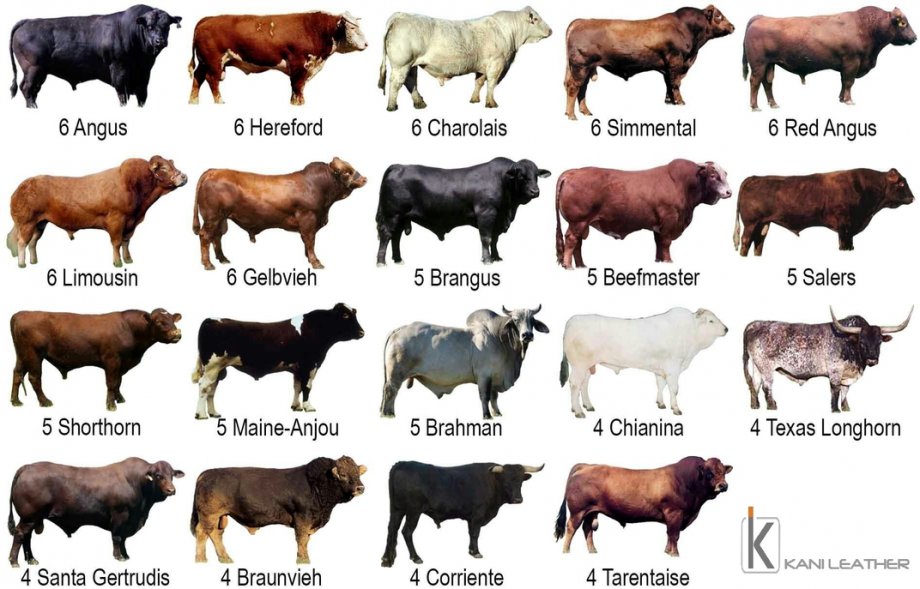

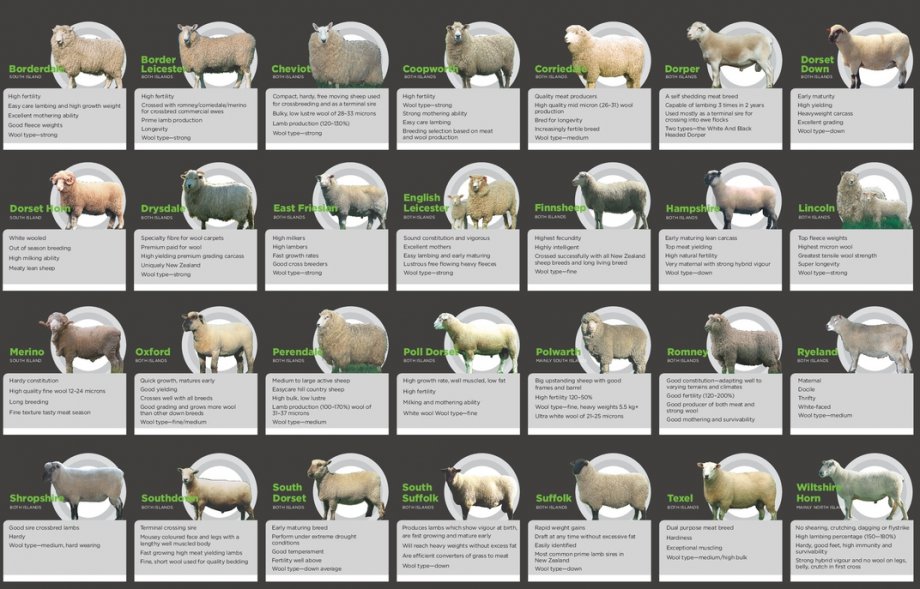

According to the animal hide

As is acknowledged, we will find many kinds of leather that are differentiated according to the animal used to make them, wanting to mention the major ones:

- Bovine hides (cows, oxen, bulls, calves, etc.)

- Sheep and goat skin (rams, sheep, lambs, goats, cross-breeds etc.)

- Exotic leather and skins (ostriches or reptiles such as crocodiles, snakes, lizards, iguanas etc.)

- Fish skins (wolf fish, salmon, eel etc.)

- Fine fur coats (minks, foxes, opossums, etc.)

- Skins of wild animals (deer, wolves, fallow deer, gazelles, etc.)

Definitely, the first two varieties are the most widely used, as they are those with the least environmental effects and do not affect the terrestrial wildlife, since the skin is a renewable substance with regard to the main need to feed the populations.

According to the finishing of the surface

Subsequently, the leather obtained from the first stages of tanning will move to the finishing method, a process by which the leather adopts the colour, strength and quality characteristics that allow it to be used in the most varied fields. The key processes of completing, without being too technical, are the following:

Crust or semi-finished leather: in the event that it is not fully finished, but left in the natural state after pre-tanning and tanning, it is the name that takes the leather or skin.

Aniline and Semi-Aniline Leather: It is a form of finish that leaves the skin surface exposed and clear to the naked eye (also known as the grain side). The procedure is carried out by immersing the skin in clear dyeing tanks, which helps the color additive to retain clear pores typical of the skin of the subject. In contrast with the first, semi-aniline leather often envisages a light use of covering pigments, aimed at preserving and uniforming the surface and partially masking the defects.

Pigmented Leather: particularly in the final display, it differs from the leather finished with pure aniline. As we know, aniline standardizes the surface and the color that comes out of the bath dye, but it does not fully remove any imperfections or defects that are present on the vast majority of skins sent for production; for this purpose, it is common to use corrected-grain leather. Each skin has distinctive features and defects that can differ with respect to various variables. We do not want to reflect here on the origin and essence of these defects: let's just assume that aniline finishing most frequently accentuates rather than limits the natural defects. Therefore, it is appropriate to resort to some kind of escamotage, in particular through the use of pigments, it is possible to disguise defects more or less heavily; the distinction between aniline, semi-aniline and pigmented leather also stems from this process. The more huge the pigments are given, the more the skin moves away and becomes specifically pigmented from the pure aniline finish. Part of the naturalness is lost with pigmented leather, but at a much more affordable price, a great uniformity of the leather is achieved. The processing techniques of this type of leather, often referred to as corrected grain leather, have now achieved a degree of such refinement that it sometimes gives a very friendly appearance and is especially valued by the industry.

Printed leather: a type of leather, aniline, semi-aniline or pigmented leather that has undergone a printing process carried out by means of special presses or rollers that impress or draw unique textures by Kani Leather on the skin in order to mimic the features of certain animals ( e.g. reptile leather) or to replicate fantasy designs.

Dry-Milled Leather: you do not hear of this form of finish very much, it is in reality a strictly scientific word which refers to a specific leather finish. It is a procedure that includes putting the skins into certain drums that give the leather an aged and wrinkled look by movement and fire, giving it a specific and different appearance. This method of processing will be carried out on a wide range of leathers, from deer to calf or ovine hides, the preference of the purchaser would be in any event. You can select the quality of leather from Kani Leather, the color type, the surface finishing and finally the potential milling effect, depending on the object or item you choose to make. You can make various items, accessories and garments with this style of work, it's just a matter of taste and creativity and the produced goods would have the added benefit of a special, raw and unrepeatable texture.

Suede: it is a surface finish obtained by tanning and finishing the "break", the least "noble" layer of the skin of the animal. It has a soft and silky presence and is generally tanned with chrome.

Nubuck: It is a finish on the grain side of the leather that is sanded to achieve a velvety, smooth and refined surface, similar to suede but more costly and expensive.

Although these styles of leather and leathers are the most prevalent, it is important to understand that the types of leather and leather finishing do not end with this list for the sake of authenticity, but there are many others that are not the focus of this article, such as patent leather, polished, buffered, laminated, nappa, greased, hair-on, etc.

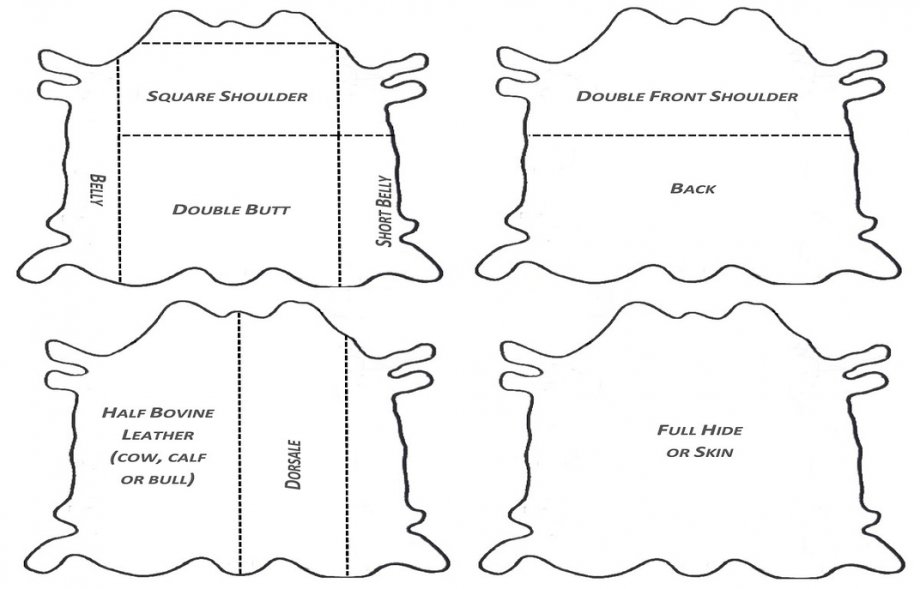

According to the cut and the shape of the hide

Skin and leather forms may also be categorized and graded on the basis of how the skin is trimmed, or on the basis of the form of the animal itself, which clearly affects its application, as, for instance, very small skin may not be the most appropriate for producing long belts. We find the following among the key types:

- Half skins: such as calf sides, cow sides

- Bovine shoulders

- Bovine double butts

- Dorsal

- Bellies

- Backs

- Culatta

- Double front shoulders

Each cut has its own characteristics and uses, and is typically tanned and finished to the form and thus to the usage that it requires to be rendered in the most suitable way. As an clarification, the subdivision scheme of a whole bovine leather is given.

Types of leather according to the intended purpose

Finally, several types of substance may be classified depending on the intended use of leather:

- Types of handbag leather: this type usually contains not too thick chrome and vegetable tanned calf skins, cowhides, sheep and goat skins.

- Types of furniture and upholstery leather: we also find generously sized skins in this type, such as entire cowls or bull hides.

- Types of clothing and leather jacket: comfortable and light, also known as nappa leather, with a thickness of less than one millimeter, typically lambs, rams and calves

- Shoe leather types: These hides are between 1 and 2 millimeters (3-5 oz.) thick and can be of the most diverse kinds and finishes.

- Belts and saddlery leather types: they are typically vegetable tanned leather hides with a thickness of more than 2 millimeters (6 oz. and up), such as double butts or shoulders of a bull, but any form of leather could be used for this purpose if it were lined.